- Email Address: info@eibc.in

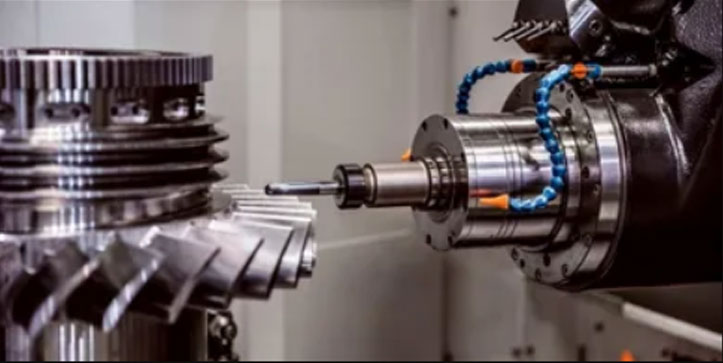

Our Products

About Us

EIBC is one of the largest Distributors for Bearings in India

Our Head Office is in Mumbai, India. The company was founded in 1968.

We stand for our Ethical Standards, Professionalism in the way we conduct our business and Quality of Service which we provide to all our customers.

Catering to over 8,000 clients nationally and globally with our superior technical support team, honest pricing, planned inventory management which supports shortest lead time, we have been the undisputed leader for bearings in India.

Read More